Georg Pit, Willroth

Georg Pit in 1903.

In the foreground: grate ovens and loading facility.

All pictures from the picture archive: Jürgen Kalscheid, Willroth

The history of mining in Willrother has been documented since the 14th century. In 1338 iron ore mining in the Horhausen area was first mentioned in a document. Until 1771 it was mostly operated by self-employed workers.

From 1771 the Kurtrierische Staat took over the Horhausen mines in order to supply the Sayner Hütte with their ores. Between 1803 and 1815 the pits and the Sayner hut belonged to the Count of Nassau-Weilburg. Only then did more regular operations return, as the pits and Sayner Hütte were part of Prussia . As early as 1811, an hereditary tunnel, the "deep St. George's tunnel", was built on the Georg pit. After eleven years of construction, the tunnel reached a length of 533 m with a depth of 73 m. With the purchase of the Horhausen iron ore mines by Alfred Krupp in 1865, an accelerated mechanization of mining began. Two years later, Krupp had a machine shaft sunk at the Georg pit.

This initially received a 20 HP steam engine for promotion . The shaft already had a depth of 155 m in 1885. The entire depth of the shaft was last 968 m in 1965.

In the years 1898/99 a cable car was built to the Louise mine for the further transport of the ores.

This was used until the mine was closed in 1930. In 1892 the Girmscheid mine, located in the municipality of Gierene, was consolidated with the Georg mine. It had been in operation as Wiedische Grube since 1803.

In 1926 the "Sieg-Lahn-Bergbaugesellschaft mbH" acquired the Georg mine and modernized the plant two years later. It got new electrical conveying and processing systems and a new wash house . In the course of the global economic crisis, the production on Georg was stopped around 1930. Production was briefly interrupted towards the end of the Second World War. In the autumn of 1945, the promotion was resumed with 535 employees, funded by the Marshall Plan and later with funds from the coal and steel union .

In 1952 a second shaft was sunk. This was 913 m deep and received a 56 m high headframe, which is still standing today and can be seen from afar (industrial monument since 1988). From 1953 the Georg mine owned belonged to Erzbergbau Siegerland AG . In 1964 the workforce numbered only 370.

The daily output was last 740 tons. On March 31, 1965, the last shift was moved and the mine officially closed on May 21, 1965. Grube Georg and Grube Füssenberg were the last in the Siegerland and Wieder districts.

Photo of the Georg pit from August 30th, 1886.

Photo taken in 1934. The first "Labor Day" pageant at the Georg mine after the global economic crisis.

Aerial photo from 1957 with a view of the 2 shafts of the Georg pit. The old shaft on the left and the new shaft on the right.

The working world of a miner on the

Georg Pit from 1950 to 1965.

The washhouse: the work clothes are hung on a chew hook and pulled up to the ceiling with a chain.

The laundry room: after work you had the opportunity to wash yourself.

The carbide booth: This is where the carbide lamps for the next shift were kept. Each lamp had a number.

Start of the shift: a group of miners gathered in front of the cage. Waiting for the next ride!

Drilling for the next blast.

Detail shot. So that there was no dust during the drilling, water was supplied through a small hole in the drill bit. The quartz-containing dust was responsible for the development of the occupational disease "silicosis", which some miners suffocated after years of hard work.

With the help of a wooden stick, the detonator with the detonating cable is pushed into the borehole. Here you can see the vein (siderite) very nicely!

Now the ignition takes place!

Finally a break! Miners playing cards. Since the job of a miner could be very dangerous, the cohesion of the miners (another name for miner) was very important.

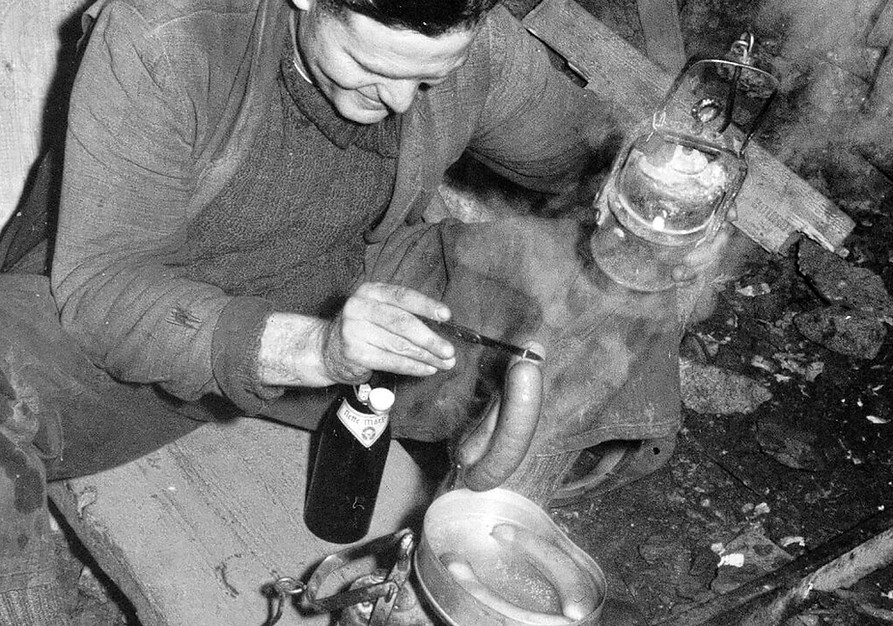

Another miner on the 550 m level makes hot sausages for breakfast. Warmed up by the flame of his carbide lamp!

After the blasting work, the tidying up with the help of an overhead loader follows.

The iron ore is loaded in a mine car.

The iron ore goes over a stretch (here with timber construction) towards the filling site.

When it arrives at the filling point, the iron ore is transported upwards via the conveyor cage.

The conveyor machine operator is notified via a bell signal.

The conveyor machine operator at his workplace.

Miners on the 550 m level. With a dump truck, it was easier to transport mountains backfilled (secondary rock to fill in excavation cavities) to the destination.

550 m level: an excavation filled with an offset. The work of a miner is not only particularly dangerous, but you shouldn't be afraid of the dark and cramped areas.

_edited.jpg)

View of the headframe of the old shaft after it was closed in 1965

Mineralogical treasures from the

Darkness of the Georg pit

During the mining work of the miners, crystalline cavities were often found.

At the Georg pit, the mining of minerals was very popular, even if it was not officially allowed. If miners hit a beautiful druse with minerals, the climber had to be informed. This had then stocked up princely with great and magnificent mineral specimens.

If the Steiger was gone again, you had looked for it yourself. But you didn't have much time for that. The riser demanded to blow the gland again so that no valuable time was wasted on it.

The minerals shown here all come from the Henry Weskamp Collection, Burbach. In 2012, he had acquired a complete collection of Grube Georg. These minerals were collected in the 50s and 60s by the Steiger Erich Lück from Hollert near Montabauer.

Chalcopyrite with brightly colored tarnishing on siderite. Year of discovery: 1965. Step size 12 x 11 cm.

Photo: Matthias Reinhardt.

Bournonite on siderite from the 600 m level. Year of discovery: 1959. Step size: 15 x 8 cm. Photo: Matthias Reinhardt.

Bournonite on siderite. An absolute top level From the 640 m level! Found in 1962.

Step size: 12 x 8 cm. Photo: Matthias Reinhardt.

Tetrahedrite with chalcopyrite on siderite. Image width: 18.5 mm. Photo: Matthias Reinhardt.

Tetrahedrite on siderite. Image width: 18 mm. Photo: Matthias Reinhardt.

Bournonite on siderite and quartz. Image width: 30 mm. Photo: Matthias Reinhardt.

Bournonite on siderite and quartz. Image width: 12 mm. Photo: Matthias Reinhardt.

Minerals from the collections

former miners

Chalcopyrite on siderite from the 800 m level. Step size: approx. 35 x 17 cm.

Collection: Werner Groß, Obersteinebach. Photo: Matthias Reinhardt.

Bournonite with chalcopyrite. Step size: 12 x 10 cm.Collection: Verbandsgemeinde Flammersfeld.

Photo: Matthias Reinhardt.

Pyrite on siderite. Image width: 25 mm.Collection: Verbandsgemeinde Flammersfeld.Photo: Matthias Reinhardt.

Tetrahedrite on siderite. Image width: 27 mm.Collection: Verbandsgemeinde Flammersfeld.Photo: Matthias Reinhardt.